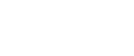

Dual-chamber Furnace

Use aluminum liquid pump to deliver aluminum liquid, in the melting room melt the aluminum material (blocks, plates, bags lump) with almuinum liquid

Key words:

Category:

Product Details

The equipment comprises the following parts:

Furnace components: Heating chamber, side well (melting chamber), aluminum liquid pump, ash disposal chamber, and regenerative burner.

Auxiliary heating and conveying system: Material hopper, elevator, magnetic separator, heater, and flue gas treatment furnace.

The aluminum liquid pump is employed to transport aluminum liquid. The aluminum material (such as ingots, plates, and bagged lumps) is melted in the melting chamber using the aluminum liquid, with the aim of reducing fuel consumption.

EquipmentFeatures:

The furnaces come in a full range of capacities from 10 to 120 tons.

The use of aluminum liquid pumps in dual-chamber furnaces for melting recycled aluminum represents the most advanced equipment in the recycled aluminum melting industry today.

During the melting process, aluminum loss is low, the equipment is highly automated, and the operating environment is friendly to workers.

The definitive first choice for large-scale recycled aluminum melting projects across the globe.

Twin-chamber Melting Furnace

Furnace capacity: 10 – 150 tons

Melting rate: 1 – 20 tons/hour

The twin chamber melting furnace process offers an efficient and economical way to melt aluminum scrap. Aluminum recycling with the twin chamber melting furnace (TCF) is applicable to end-of-life and production return scrap – both loose and packed – with or without adhering contamination.

1.Near continuous heating – charging and melting

2.Extremely Low energy consumption

3.Flexible possibilities of melting different types of scrap

4.High melting performance

5.Environment friendly

6.Applied vortex technology

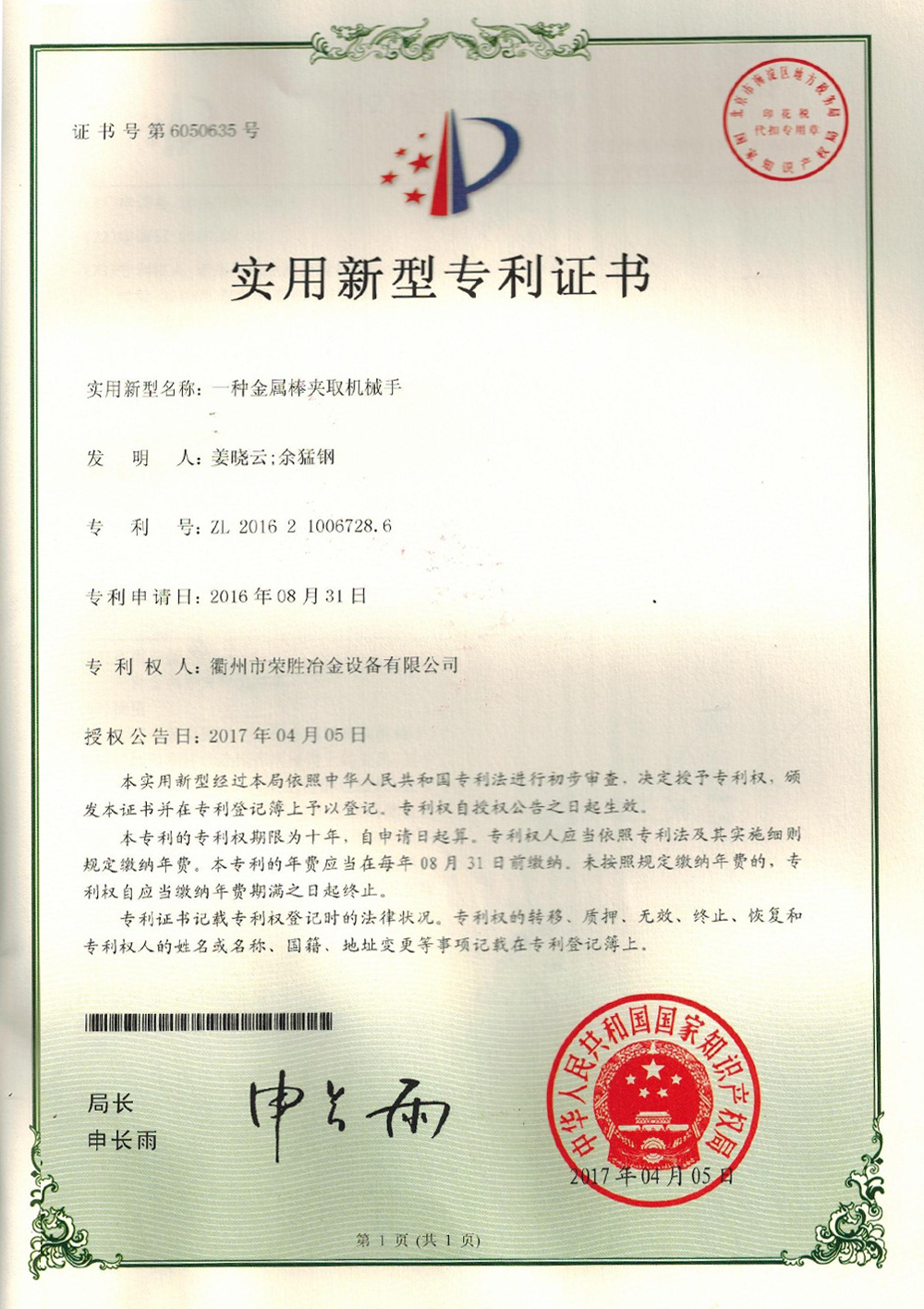

Certificates

Cooperative Clients

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote