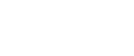

Product Details

Working principle:

The regenerative burner system comprises at least two burners, two thermal accumulators, a heat recovery system, and corresponding control devices. The burners and thermal accumulators can be directly connected based on actual conditions, or optionally connected through piping cast with refractory materials.

When one burner combusts using hot air from the regenerator, the other serves as an exhaust outlet, using a blower to release hot air through the burner into the regenerator for heat storage. When sufficient heat is stored, the butterfly valve activates to switch the roles of the two burners. Whenever one burner is combusting, the other assists the accumulator in storing heat. During heat exchange, the exhaust temperature in the piping typically ranges from 130-200°C, enabling both the butterfly valve and the blower to operate safely and reliably over an extended period.

Applications:

Aluminum melting furnaces, etc.

Specifications:

300kW – 6000kW

Fuels:

Natural gas, heavy oil

|

|

|

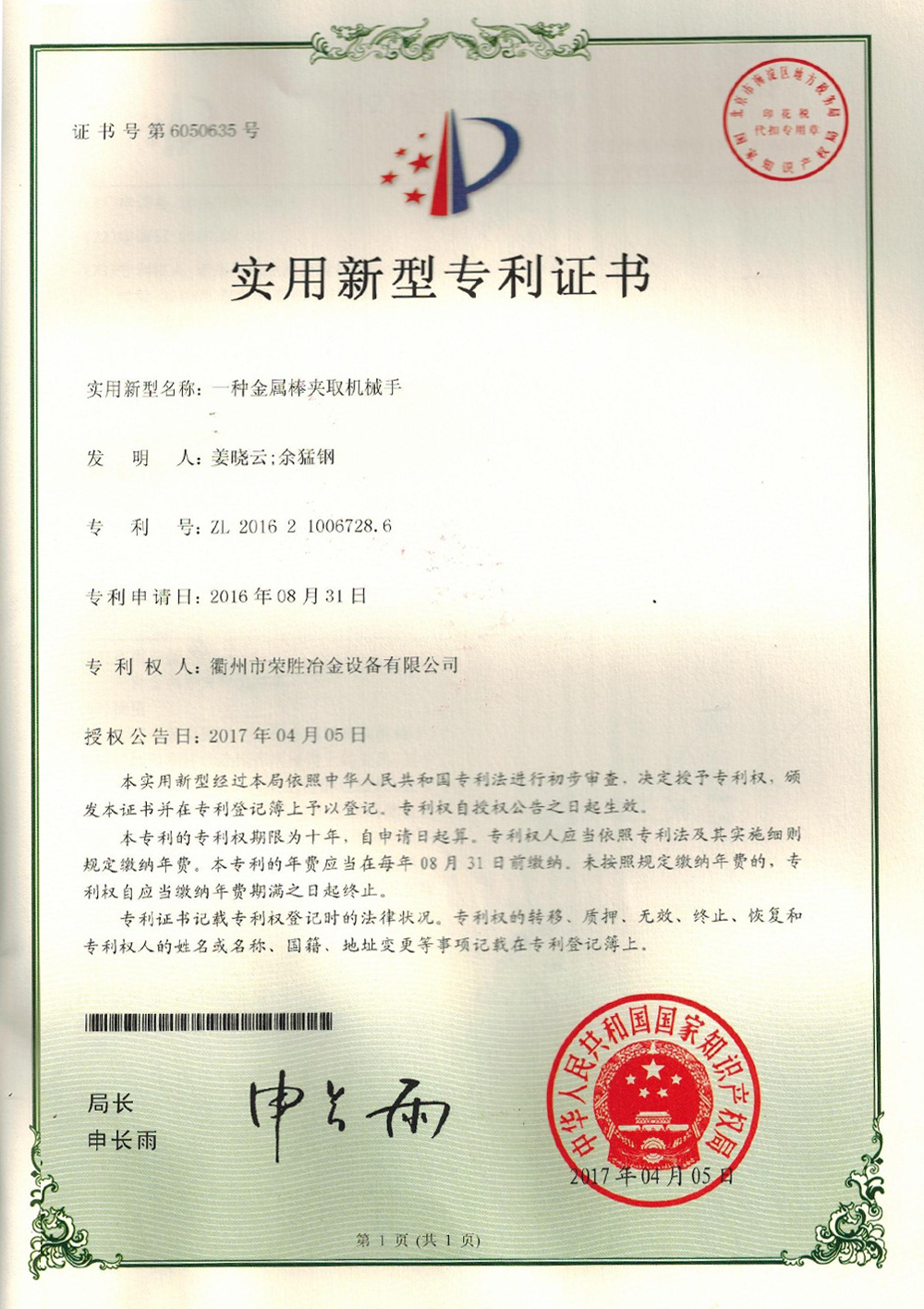

Certificates

Cooperative Clients

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote