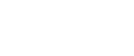

Ash rotary furnace/Cold Ash Bucket

This equipment is suitable for processing large volumes of hot aluminum dross and aluminum dross with high iron content. It only requires one skilled forklift operator. Specifications: 2-8 tons

Key words:

Category:

Product Details

Ash rotary furnace

The device is Suitable for processing large quantities of hot slag, slag and containing high iron aluminum slag. Staffing less, only need a skilled forklift operator and a helper, can deal with a few tons to hundreds of tons of cold aluminum dross one day, that is high efficiency. The heat slag rake out from the furnace, and use rotary forklift sent back to rotary furnace, with the reverse rotation of rotary furnace and back and force stir of rake in forklift can separate aluminum water from aluminum slap. Should be noted to control the temperature during the operation, and can add cold slag and little aluminum as a temperature control agent and secondary refine. After processing is complete, use hydraulic cylinder tilt to jack up the rotary furnace barrel body to pour out aluminum water, after pour aluminum water rotate bucket body can dump ash, it’s easy to operate. The recovery rate of aluminum water in aluminum slag can be over 80%, if support the use with screening cold ash bucket, comprehensive recovery can be over 90%. Rotary furnace and screening cold ash bucket are the ideal equipment to replace crucible and Vertical fired ash machine to handle large quantities of cold aluminum dross and slag.

Specification: 2-8t

Cold Ash Bucket

1. The primary function of the cold ash bucket is to rapidly cool the hot ash from the rotary furnace after aluminum extraction through water spray heat exchange, thereby reducing the burning loss of aluminum in the ash. Additionally, large pieces of aluminum slag are crushed by pressing rolls installed inside the cold ash bucket to enhance the separation rate.

2 .The cylinder body operates on friction-driven tracks supported by rollers, which avoids gear engagement, reduces noise, and ensures reliable operation. To handle the large amounts of steam generated from water spraying, a fully enclosed structure is adopted for the spray section, preventing adverse factors such as obscured visibility in the workshop due to steam diffusion.

3. The electric valve behind the dust hood can achieve linkage with the rotary furnace and the cold ash bucket.

4. Variable frequency speed regulation is employed.

Certificates

Cooperative Clients

Previous

Previous

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote