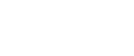

Product Details

1. It is used for the transfer of aluminum liquid between the melting furnace and the holding furnace, which can reduce the height difference between them. This makes the pre-furnace operations efficient and quick, and allows for a more reasonable workshop layout.

2. It is used to supply aluminum liquid from the melting furnace to the ladle, eliminating the need for frequent opening and closing of the tap hole, thus enhancing safety and efficiency.

Eventually, after the aluminium alloy has been melted in the melting furnace, it needs to be transferred and/or delivered to the next operation within the casting process. With the transfer technique of using a transfer pump, the pump remains in the furnace well and is activated whenever metal delivery is required. Liquid metal is pumped above the liquid metal line of the furnace for discharging to the end use point. Transfer pumps can be classified in two groups: conventional and overflow pumps. Main benefits of transfer pumps as compared to transferring techniques using tap blocks or tilting furnaces may include:

1.Cleaner molten metal

2.Faster transfer times

3.Lower molten metal temperature loss

4.Better safety

5.Lower capital costs

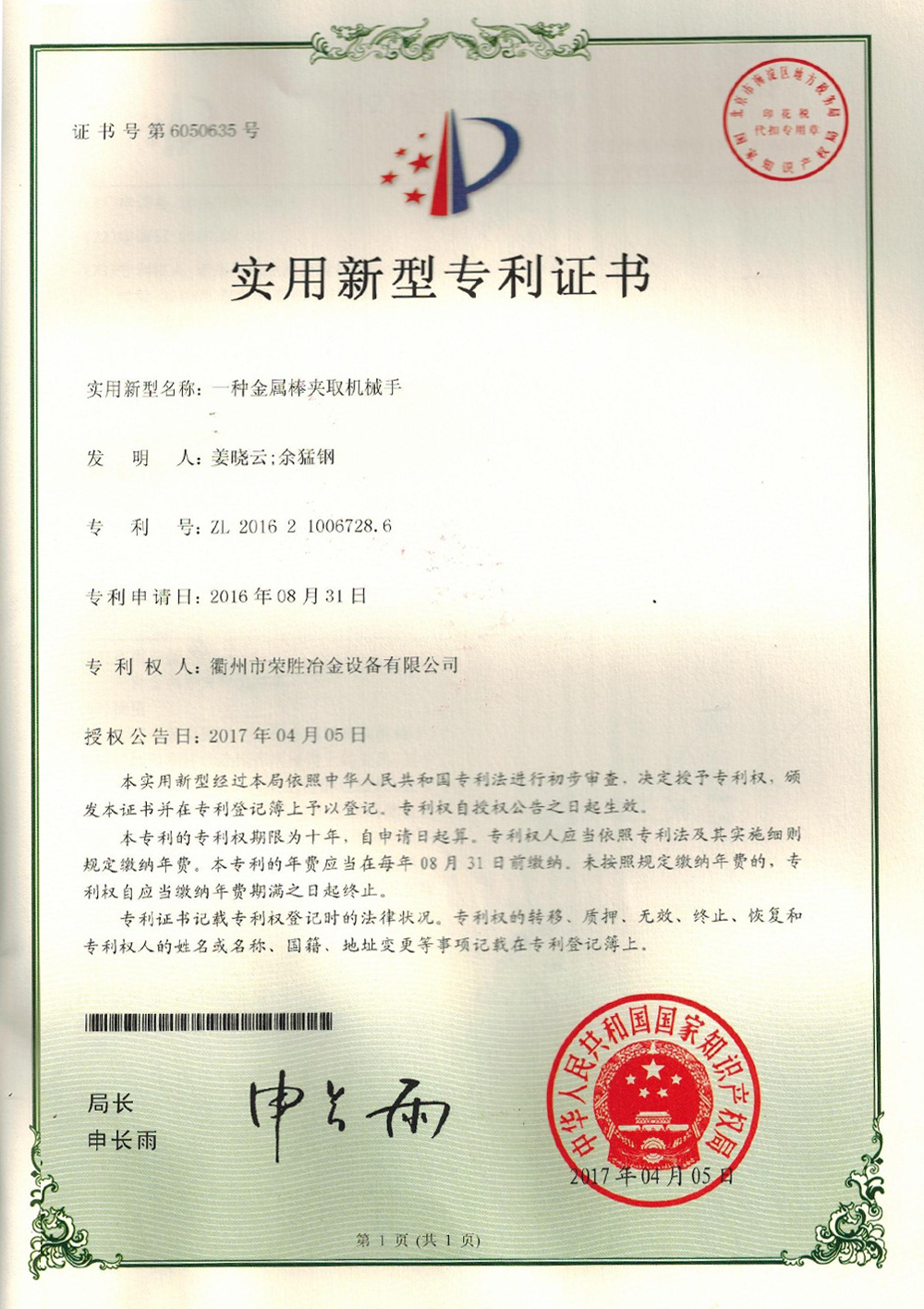

Certificates

Cooperative Clients

Previous

Next

Previous

Next

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote