Ingot Stacking Machine

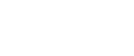

After the liquid Aluminium flows into the distributor of casting machine, it’s uniformly injected into the machine by distributor and the Ingot mold is carried water sprinkler to cool.

Key words:

Category:

Product Details

Process outlined

After the liquid Aluminium flows into the distributor of casting machine, it’s uniformly injected into the machine by distributor and the Ingot mold is carried water sprinkler to cool. Ingots sufficiently cooled and solidified forming and through pneumatic releasing ingots falling on activities conveyors and front conveyor, then transported to the stacker position,

The finished ingots will be automatic stacked according to the prescribed procedure by stacked spindle machine. After that they will be transported by the back conveyor to the packing place, then transported to the reservoir by the factory forklift.

Configuration

1,The role of process control of stacke spindle: Neatly arranged Aluminum ingots go in to the stacked position, the spindle stack robot gripping, lifting, rotating and moving, then the robot stacke according to set procedures. Each layer of the stack at an angle of rotation, every rotation different from the other angle of 90 degrees. The height of packing corner difference for 3% or less.

2,The role of product conveyor: receive stacked ingot robot transferred ingots, and move the stacked packing to the top oil cylinder. Then top ingot oil cylinder rises to be removed by a forklift or other means. Conveyor consideration of not less than two Packing storage area.

3, The role of the hydraulic system: to provide power for each hydraulic cylinder and control the action of each cylinder.

4, The role of the pneumatic system: Control various actions of pneumatic devices,

5, The role of electrical control system: control and protect the operation of each device.

6, Electric Transmission: 380V 50HZ three-phase four-wire system, motors and other electrical equipment have overcurrent, short circuit transient voltage shock motor overheating protection, electrical junction box next to the device is closed.

Characteristic

China's first stacked spindle machine with the function that can detect the front and back of aluminum ingots and automatic spindle turning. It’s only need one person to operate compare to peer products, clear the design drawbacks of the conventional stack machine that effort but waste manpower.

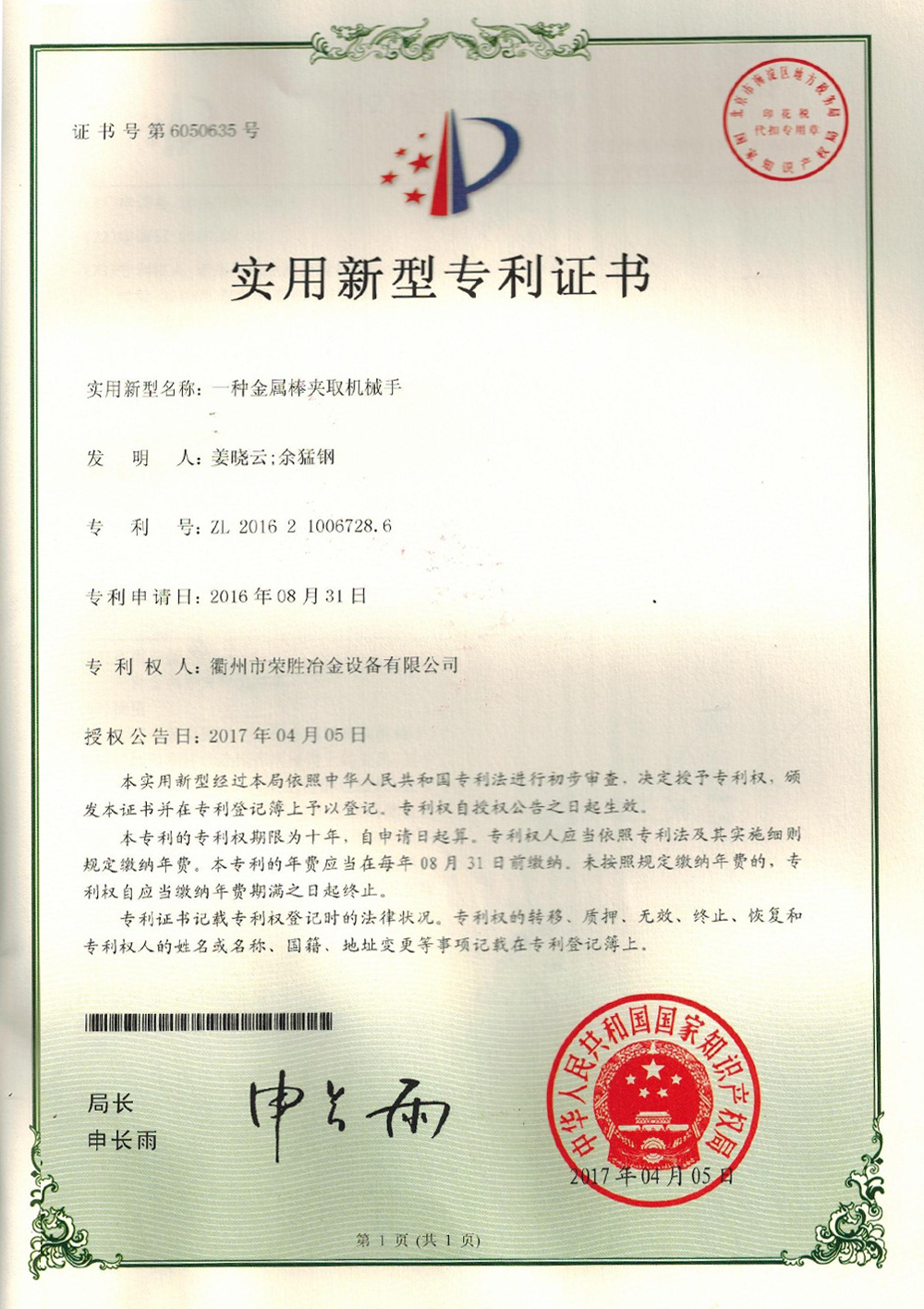

Certificates

Cooperative Clients

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote