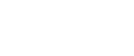

Fixed Casting Degasser

Fixed casting degassing device is the refining equipment outside of furnace that suitable for casting

Key words:

Product Details

Fixed Casting Degasser

Fixed casting degassing device is the refining equipment outside of furnace that suitable for casting, using argon or nitrogen as refining medium to remove hydrogen, metallic and non-metallic inclusions from the aluminum melt.

Fixed casting degassing installed at a fixed location, working by moving the ladle to get the quantitative refined gas into the melt through high-speed rotating Graphite rotor. By relatively high shear of graphite rotor and aluminum liquid to generate tiny bubbles and uniformly distributed in the aluminum melt. Because pressure of hydrogen in the bubble is zero, and it’s opposite in the aluminum melt, thus the hydrogen in the liquid aluminum gradually spread to the bubbles. Meanwhile, metal and non-metallic inclusions in the liquid aluminum are adsorbed on the surface of the bubbles, and inclusions are come-up with the bubbles, that leads to the result to remove the hydrogen and inclusions.

In-Line Launder Degasser

High efficieny: Device using a multi-stage degassing design, there’s three graphite rotors to degas in the launder, thus form a large convection inside the degassing tank, and small bubbles can spread completely in liquid Aluminum. that increase the contact surface of the bubbles and liquid aluminum. Meanwhile degassing tank using a sealed design, put an end to the outside air get in and caused the secondary pollution, improve the efficiency of degassing.

Low cost: Device using the method that launder degassing to replace online refining equipment necessary for liquid aluminum heat insulation system, thus maximize the reduction of the device power consumption during use.In the mean time,as with the launder degassing, the residual liquid aluminum is less, that reduce the metal loss.

quick conversion: Device using launder degassing,it could empty the liquid aluminum after casting, Greatly facilitate the rapid conversion of alloys, Eliminating the wash for degassing device when alloy conversed. That could reduced metal loss and more productivity.

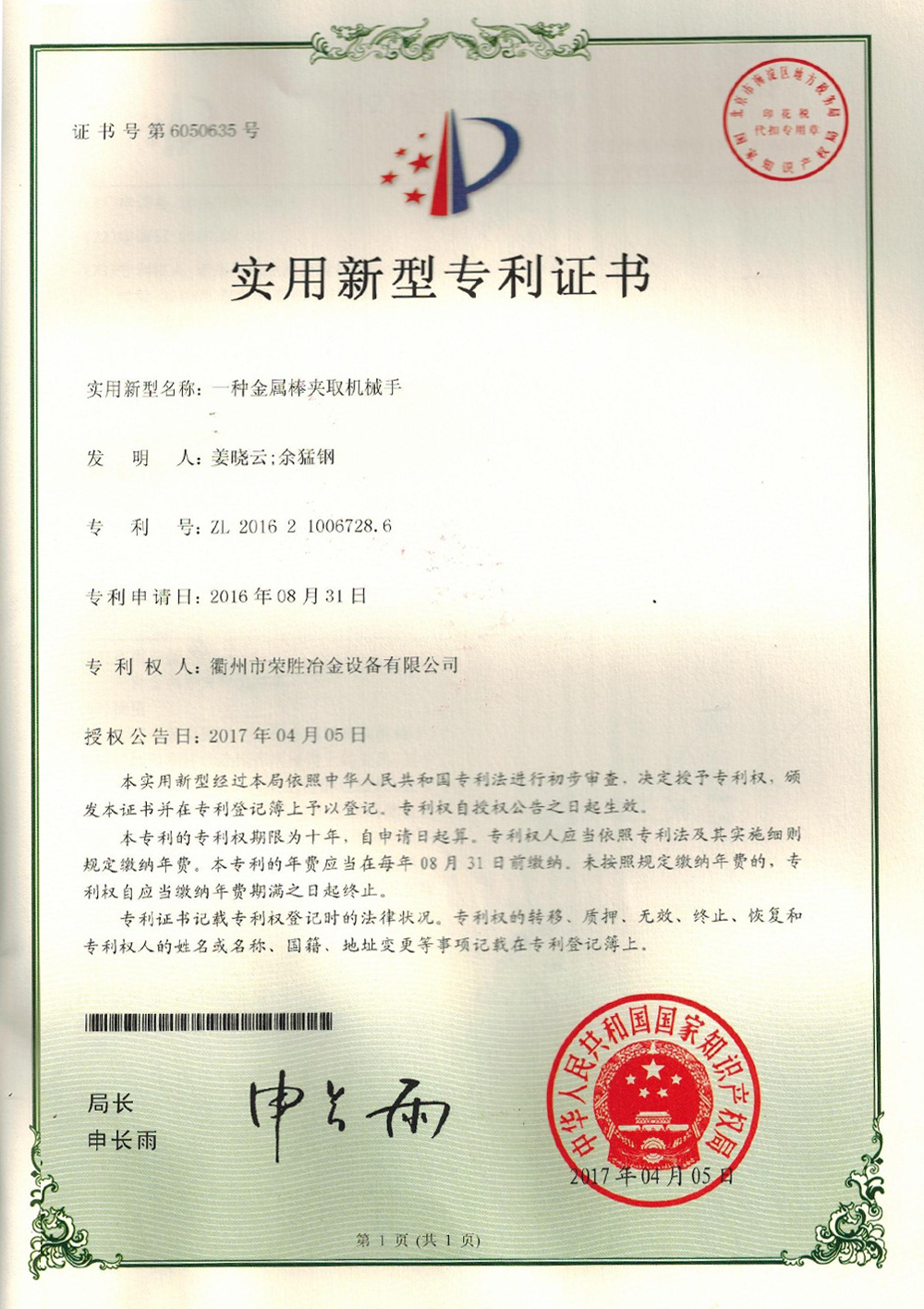

Certificates

Cooperative Clients

Previous

Next

Previous

Next

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote