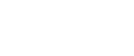

Product Details

1.Adequate and Uniform Mixing: The permanent magnet stirrer provides thorough and powerful mixing, generally achieving the desired results after 20 minutes of stirring. This eliminates the variations in chemical composition uniformity caused by factors such as operating conditions, skills, physical strength, or work attitude under mechanical or manual stirring conditions.

2.Enhanced Melting Efficiency and Reduced Energy Consumption: The permanent magnet stirrer can start stirring when there is one-third of the liquid in the furnace, thereby accelerating the heat exchange between the liquid and unmelted charge. This speeds up the melting rate of the charge, typically improving melting efficiency by 15% and reducing energy consumption by 10%.

3.Robust and Durable Equipment: The permanent magnets of the permanent magnet stirrer undergo high-temperature and aging-resistant processes, resulting in a lifespan of over 10 years. The product features a simple structure and high reliability, requiring minimal maintenance. It consumes low energy and generates no pollution.

4.High Degree of Automation: The control system of the permanent magnet stirrer enables remote control, offering a high degree of automation and ease of operation. The equipment is equipped with a lifting system at the bottom, allowing for the adjustment of the gap between the magnetic system and the furnace bottom according to the height of the furnace bottom.

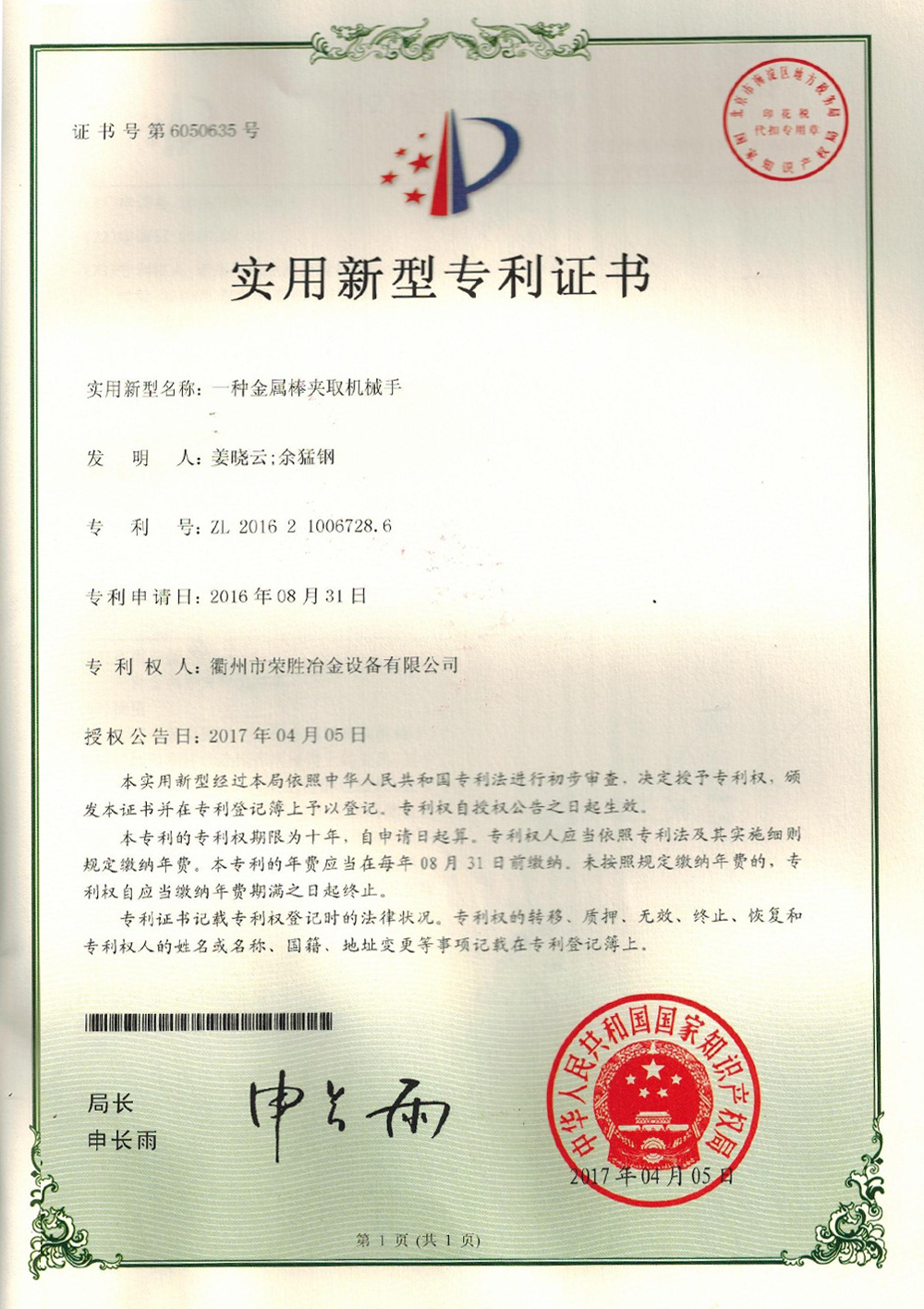

Certificates

Cooperative Clients

Related Products

ONLINE MESSAGE

*Note: Leave your contact information to get a free product quote