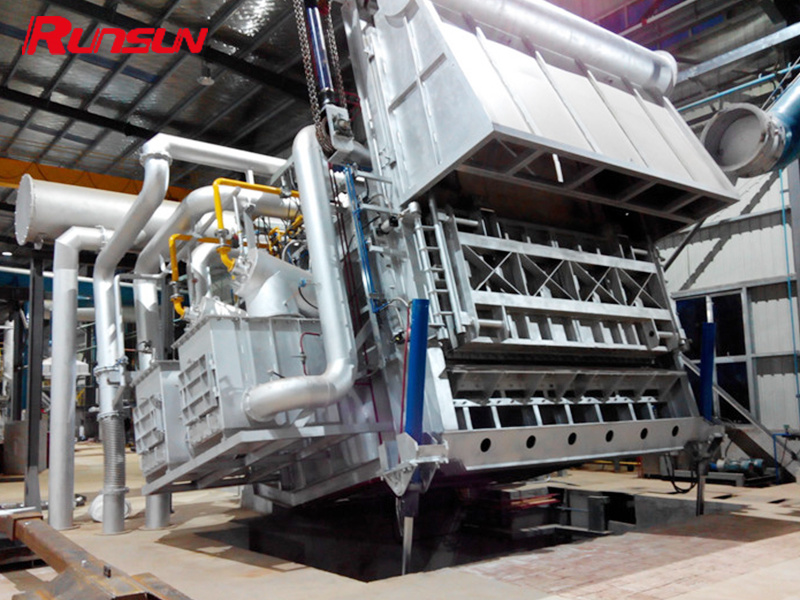

Supplier of Comprehensive Solutions for Secondary Aluminum Melting and Casting - Offering Complete Solutions and One-Stop Services

RUNSUN

The main products of the company

various types of aluminum metal melting furnaces

Get in touch !

Hi, we're RUNSUN.

Focus on recycled aluminum melting and casting

Founded in 2005

Product patent

Global partner

Number of employees

The main products of the company include various types of aluminum metal melting furnaces, recycled aluminum melting furnaces, UBC melting systems, paint stripping systems for recycled aluminum (UBC), heat preservation furnaces, regenerative burners, aluminum liquid transfer pumps, flue gas and dust treatment systems, automatic aluminum ash treatment lines, ingot casting systems and so on.

Recycled aluminium melting and casting !

01

MANUFACTURING

The factory is equipped with high-quality production equipment, a complete performance laboratory

02

SERVICE

A professional technical team to ensure that the quality and performance of products reach the highest standards.

03

QUALITY CONTROL

Testing reports such as ISO9001 quality system, and won the honor of high-tech enterprises, specialized and special new enterprises.

04

We will make unremitting efforts to provide you with excellent products and services to create a better future!

Blogs

Focus on recycled aluminum melting and casting

The leading caster in India, SBA, paid a visit to Runsun

Sep 02,2025

Recently, a high-level delegation from SBA (Shree Balaji Alloys), a leading recycled aluminum casting enterprise in India, visited our company.

Sep 01,2025

The development of secondary aluminum melting equipment has undergone a process from simplicity to complexity and from low efficiency to high efficiency, with the core objectives of improving thermal efficiency, reducing burnout rate, minimizing energy consumption, and mitigating environmental pollution.

Advantages of Utilizing Regenerative Burners

Jul 16,2025

Regenerative heat exchange technology has revolutionized traditional combustion methods. It primarily manifests in that fuel and air enter the furnace through different channels at appropriate velocities and mix with the combustion products inside the furnace. The 21% O₂ in the air is diluted, and the fuel burns under high-temperature (above 1000°C) and low-oxygen concentration (5-6.5%) conditions within the furnace chamber.